Production Innovation

Frames:thick changed into thin

This make our mirror becomes lighter and more stylish and beautiful.

Light: Originally we used the ordinary light,now we use LED light instead of it.

Ordinary lights can be used 1000 hours,but the LED can be used for nearly 60,000 hours,so the life of our mirror will become longer.

Switch: the switch of the mirror is changed from a button switch to a touch switch, and then to aninductive switch;the power comes from alternating current to battery to rechargeable battery.

These advances have made our mirrors more stylish, longer to use, more hygienic and environmentally friendly.

Design Concept

Brief but not simple

When LEVE design the mirrors,our R&D team not only focus on product appearance or structure, but also attach great importance to product features.Through repeated revises and discussions, We ensure that every mirror is suits for the requirements of customers: Beautiful, Safe and Environmental Protection.

Technology

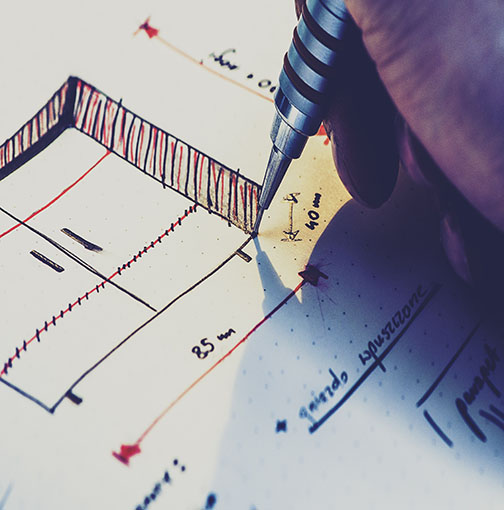

Every step of the production will affect the quality and delivery of the mirror.

We repeatedly test the materials, select the most suitable one to make them welded or stamped by using punching machine, milling machine, CNC numerical control machine tools.

LEVE is equipped with a stable and experienced polishing team and plating team,and the mirrors will be polished and plated by our workers.They know how to work with different polishing/plating methods to deal with different materials.The mirror installation and packing is done by the assembly team,we will check the goods before shipment.